Pick-to-light order picking

|

The order picking of the future, paperless and faster!

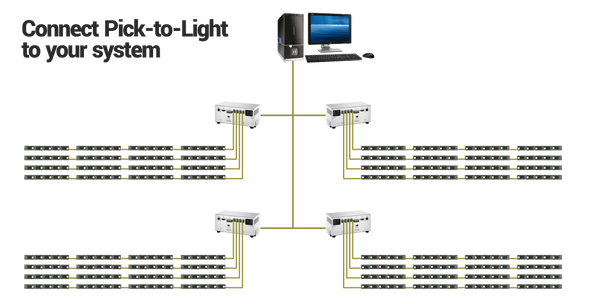

With a Pick-to-Light system also called Put-to-Light, every warehouse employee can get to work quickly. It is paperless warehouse solution and reduces the chance of errors. Pick-to-Light is particularly interesting for order picking of small goods in flow racks or shelves, where smaller locations are close to each other and the picking density is high to very high. Pick-to-Light indicates with lights where the order picker should be. Warehouses with a Pick-to-Light concept are preferably divided into zones, each with its own order picker. In combination with a roller conveyor or conveyor belt, the orders are collected — across different zones. At the start of the order pick run, the order picker scans the order number. Then all the lights within the zone where picking is to take place will light up. The display of the relevant pick location shows how many pieces have to be picked. The execution of the order is confirmed at the push of a button. |

Pick-to-Light is a user-friendly order picking system where your warehouse employee can see at a glance where the next order pick is taking place, thanks to the brightly lit display. It works paperless and reduces the chance of errors.

Every warehouse employee can quickly get started with a Pick-to-Light system. It is particularly interesting for order picking of small items with a high turnover rate in Interroll flow racks.

Every warehouse employee can quickly get started with a Pick-to-Light system. It is particularly interesting for order picking of small items with a high turnover rate in Interroll flow racks.

|

AT 800 serie

Characteristics:

|

AT 700 serie

Characteristics:

|

ST200 serie

Characteristics:

|

Pick-to-Light products brochureView our entire range of the AT700 series and the possibilities with our Pick-to-Light products from ATOP here.

We are also happy to advise you on all options. x

|

AT 400 TCP/IP Controller

|

Ideal as a signaling function for an aisle or installation to indicate the status. The TL-20R5-1BL Tower Light is controlled via Atop's TCP/IP controller (AT500/AT400).

Specifications |

Curious about our pick-to-light concepts

can do for you?

Call 0161-411916 for an appointment or email us!

can do for you?

Call 0161-411916 for an appointment or email us!