Pallet Flow Racks - Ideal for warehouses

PF 1100

|

|

Interroll Time Plus Separator Safety Matters! Interroll Pallet Flow with the pedal-less Time Plus Separator allows easy removal of the first pallet before the next pallet rolls to the pick position. Equipped with a time delay, Time Plus Separator increases safety for operator and goods and reduces risk of damages. Find out how it works! |

Interroll Magnetic Speed Controller MSC 80 for high performance when Safety counts! Control the pallet speed on your gravity lanes to avoid damages and injuries. Interroll Pallet Flow, equipped with the patented MSC 80 is a perfect solution for high performance storage applications. |

Pallet Separator ensures an even and safe removal of your pallets.Interroll's patented Pallet Separator is a mechanism within a Pallet Flow path that "isolates" the first pallet to make picking side pallets easier and safer.

The traditional Interroll Pallet Separator with TimePlus has a 20 second delay before releasing the next pallet in line. This gives the forklift driver the necessary time to safely remove the pallet from the compartment before the next pallet is released. This is extremely important when working with high-bay warehouses with limited visibility. Interroll is now launching a unique powered Pallet Separator for buffering and forwarding applications in the handling of long and transverse pallets. The innovative separator has two important advantages that are unique and set us apart from all competitors: He is extremely accurate It has consistent release time intervals for pallets The powered Separator makes sure to decide exactly when to release the next pallet, regardless of the conditions or the weight of the pallet. |

Exact Cycle Count The driven Separator allows to measure the exact number of cycles it performs. With our Interroll Lifetime Service program, you will be able to collect this crucial information. This is extremely important for two reasons:

|

PARTNER ROLLING ON INTERROLL TBWB has been a partner of Interroll for many years. With full knowledge of the facts, the Interroll systems are expertly advised and integrated by our people at our customers.

Our service is trained and equipped to provide service to your Interroll products. For Interroll products you contact TBWB. |

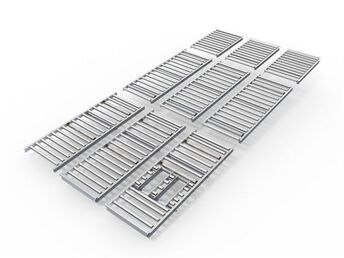

Pallet Flow | FIFO & LIFOFrom FIFO (First In - First Out) to LIFO (Last In - First Out) applications, from the buffer section to the picking and shipping section – Interroll offers a wide range of products.

|

|

First In - First Out: Principle

In FIFO configuration (First In - First Out), the pallets are loaded in the gravity lanes on the entry side (the highest point). The slope then carries the pallets from the loading point to the retrieval point. When a pallet is unloaded, the next pallet automatically takes its place thereby ensuring that the goods are constantly available. FIFO stock management guarantees stock rotation as the first pallet to be loaded in a lane is the first pallet available at the picking face on the retrieval side. This management method is particularly efficient for perishable goods. |

|

|

|

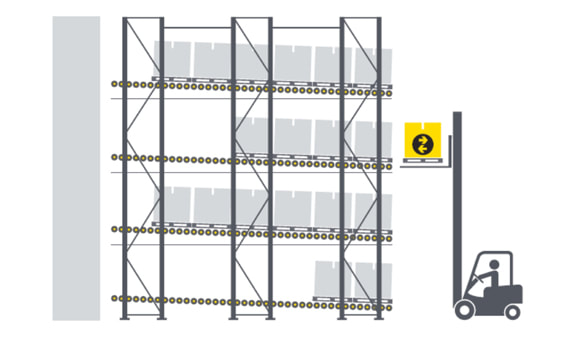

Last In - First Out: Principle

In LIFO configuration (Last In - First Out), a forklift truck loads and unloads the pallets at the picking face. This is a pushback system. To load a pallet, the forklift truck pushes the pallet at the picking face towards the back of the lane using the pallet to be loaded. When a pallet is unloaded, the pallet stored behind automatically takes its place, thereby ensuring that the goods are constantly available at the picking face. |

|

|