TBWB - Split-tray sorter, everything falls into place!

|

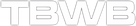

A split-tray sorter, also called a bombay sorter, bomb-bay sorter or flat sorter, is used for automated sorting of small lightweight products at high speed. These products are often too small and light to be handled by a typical conveyor system. This includes: clothing in bags, jewellery, pharmaceuticals, CDs, mail, books and small packages.

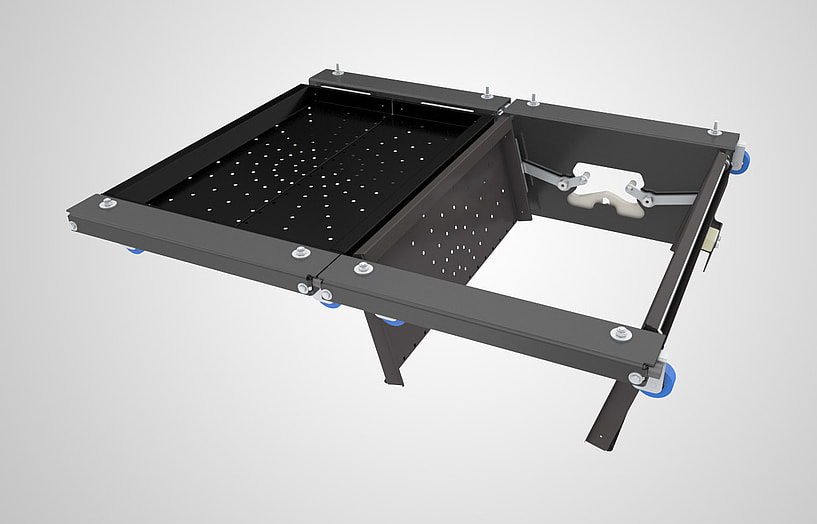

A split-tray sorter is a metal tray type sorter that transfers the product over an open order (a box or chute) and when in position, the doors swing open like a hatch to direct the product to the correct location. Advantages of split-tray sorter:

|

PARTNER ROLLING ON INTERROLL TBWB has been a partner of Interroll for many years. With full knowledge of the facts, the Interroll systems are expertly advised and integrated by our people at our customers.

Our service is trained and equipped to provide service to your Interroll products. For Interroll products you contact TBWB. Contact us today! |

Split Tray Sorter MT015S

|

At home in a wide range of industries

The compact and flexibly expandable sorters are perfectly suited for the powerful and cost-effective implementation of e-commerce or omnichannel strategies, for example in the fashion or pharmaceutical industries. Logistics service providers or courier, express and parcel service providers can use the new Split Tray Sorter to decentralize their distribution structures and efficiently separate small parts sorting from other sorting processes. Proven mechanical design The new Split Tray Sorter is based on the proven mechanical design principles of Interroll sortation systems. It ensures automatic sortation of conveyed goods weighing up to 12 kilograms - with maximum system availability, a very long service life and a short payback period. Integrated machine control The easily configurable and modular machine control system was designed for the sorter, the infeed conveyors and the end stations. It offers safety and machine protection functions. The control system can be connected to the respective goods management system. The operating status of the system can be recorded, visualized and processed in real time - an important prerequisite for predictive maintenance and Industry 4.0 applications. Simple and fast commissioning and maintenance The modular design of the Split Tray Sorter enables short project runtimes and fast delivery to the user. Thanks to the integrated machine control, commissioning on site is significantly shortened. A clever maintenance concept allows easy access to the drive station. |

-

Technical information

<

>

Speed: |

1,5 m/s |

Transit: |

10.800 items/hour |

Item types: |

small, lightweight, flat, non-breakable items, parcels, parcels and polybags, including garments, jewelry, pharmaceuticals, envelopes, books, etc. |

Maximum weight item: |

Up to 12 kg |

Drawer dimensions: |

600 x 400 mm |

The Interroll Split-tray sorter in action!

|

|

|