Nipper - Robot AGV Logistics

The Nipper is a compact automated vehicle save to use in a manned space. The Nipper is a complete independently operating AGV with a WI-FI based communication system. The Nipper only needs a loading time of just 30 minutes to be able to drive 4-5 hours continuously. The Nipper has a speed of 1 meter per second and can easily lift 1,000 kg.

De Nipper used natural structures in the environment as a reference for localization. This means it does not need any infrastructure, such as inductive wires, magnets or reflectors, to navigate.

De Nipper used natural structures in the environment as a reference for localization. This means it does not need any infrastructure, such as inductive wires, magnets or reflectors, to navigate.

|

The Nipper is a compact automated guided vehicle for unmanned internal pallet transport. It can easily lift pallets up to 1000 kg and navigate through tight spaces, making the Nipper a versatile and intelligent pallet truck. Another advantage is that after training you can program the Nipper without our help. You know how to use the intelligent software to easily adjust the routes of the Nipper, add multiple Nippers to the program and change existing commands.

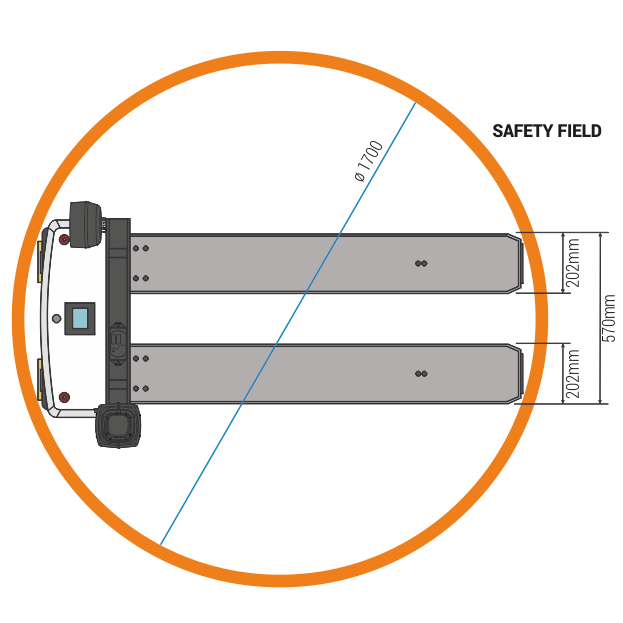

Our Nipper meets the strictest safety requirements. High-quality safety components, such as a 360° scanner and Blue Spot, have been installed to ensure the Nipper can navigate safely through manned spaces. An excellent vehicle for use in a production or warehouse environment. |

By using our Nippers in the workplace, you save a lot on manpower and insurance and increase productivity.

Optional The Nipper can be equipped with an object scanner to prevent damage from objects undetected in the security scanner field. |

|

Nipper AGV advantages:

|

Security Nipper AVG

The Nipper meets the strictest safety requirements. High quality safety components have been installed to ensure the Nipper can safely navigate manned areas.

The Nipper complies with the following safety guidelines:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

Furthermore, it is designed and built according to the following (European) norms and standards:

The Nipper meets the strictest safety requirements. High quality safety components have been installed to ensure the Nipper can safely navigate manned areas.

The Nipper complies with the following safety guidelines:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

Furthermore, it is designed and built according to the following (European) norms and standards:

|

NEN-EN-ISO 12100:2010

Machinery safety General design principles Risk assessment and risk mitigation NEN-EN-ISO 4413:2010 Hydraulic fluid power General rules and safety requirements for systems and their components NEN-EN-ISO 13849-1:2016 Machinery safety Security-related parts of operating systems Part 1: General design principles NEN-EN-ISO 13850:2015 Machinery safety Emergency stop function Principles for design |

NEN-EN-IEC 60204-1:2006

Machinery safety Electrical equipment of machines Part 1: General Requirements NEN-EN 1525:1997 Safety of industrial trucks Self-driving trucks and their systems NEN-EN1175-1:1998+A1:2010nl Industrial machinery truck safety Electrical Requirements Part 1: General Requirements for Battery Operated Trucks |

Request the desired information here

TECHNICAL SPECIFICATIONS

Performances

Supply voltage: |

24V |

Performances: |

LiFePO4 24V/2x420W/h |

Operating time: |

4-5 hours * |

Loading time: |

30min 20-80% |

Lifting: |

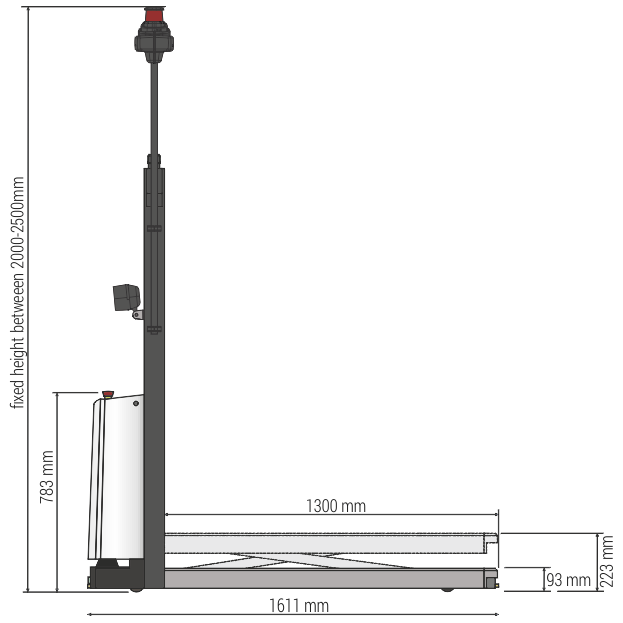

130 mm (low 93 - high 223 mm) |

Maximum speed: |

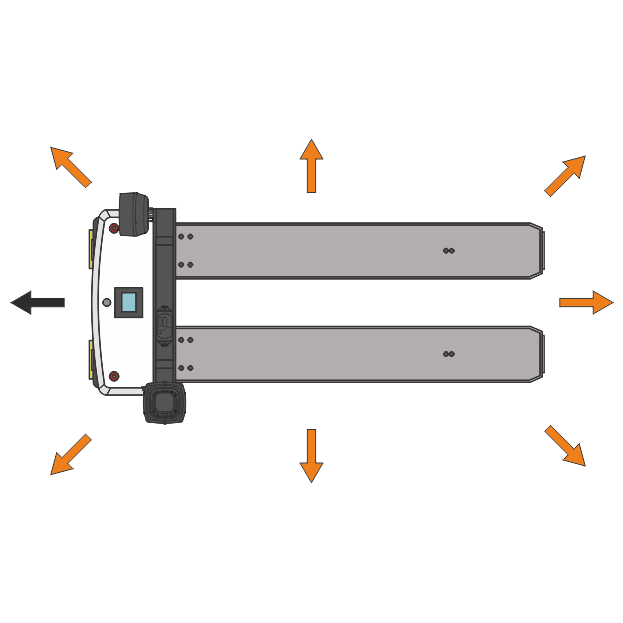

1 m / s in main direction |

Own weight: |

229 k |

TTO: |

15000 hour |

Environment

Maximum ambient temperature: |

30°C |

Minimum ambient temperature: |

0°C |

Humidity: |

95% no condensation |

CONDITIONS ON WORKPLACE

Conditions on workplace: |

dry, flat, not dusty |

Maximum bump: |

5 mm |

Maximum slope: |

3% |

pALLET LOAD

material

Frame: |

steel |

Prongs: |

stainless steel SS304 |

finish surface

Frame: |

white pearl with blank polyurethane coating black RAL 9005 textured finish |

Prongs: |

stainless steel SS304 |

Fasterners: |

galvanized steel |

Purchased parts: |

Standard supplier finish |

Control

Steering Nipper: |

PLC guided |

Language: |

English |

Navigation: |

navigation with natural characteristics |

HMI: |

3,5 ”touchscreen |

Fleet manager: |

Bluebotics |

Visualization: |

Web based |

NAVIGATIon

Scanner: |

2D Lidar 360 ° navigation scanning |

Scannertype: |

Pepperl + Fuchs 360 ° High Definition-scanning |

Scan high: |

between 2 en 2,5 m above floor level |

Charging station

Charging station: |

consists of 2 separate charges (for each prong) |

Input power supply: |

2x 230V ~ 50Hz 3,2A |

Connector: |

2x EURO-connector |

Output power: |

2x 29V-17A |

security

- Sick S300 2d LIDAR security scanner (main direction)

- Scanners in prongs for rear drive

- 2 mechanical bumpers for prongs

- 2 mechanical bumpers behind on the prongs

- Coupling limitation drive sideways (90 ° in main direction)

- Two emergency stops on the top of the vehicle

- Bluespot-warning lamp for visualization on the floor

- Orange direction indicator

- Flashing orange light for awareness on eye level in operating modus

- Red and green LED in prongs (in front of and behind) for driving indication direction

- PLd (performance level d)

security options

|

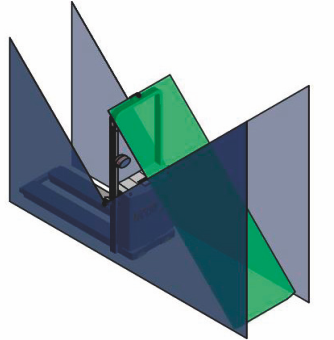

Object scanning

The object scanning solution consists of three (3) Sick TIM320 scanners, those are installed on the Nipper. Two (2) scanners on each side with a 2D vertical plan beside the vehicle and a scanner on the vehicle with a field facing slanting downwards. The Sick scanners have a field of view of 270°. The blind side of the scanners on the side are directed upwards. |

DOCUMENTATIon & REGulation

Instruction manuals: |

Manual 1x digital |

Language: |

basic English (in the EU depends in which country) |

Certification: |

CE |

Regulation: |

|

2006/42 / EG |

Machine guideline |

2014/30 / EU |

EMC-guideline |

NEN-EN-ISO 12100: 2010 |

Security of machines – General principals for design – Risk assessment and risk reduction |

NEN-EN-ISO 4413: 2010 |

Hydrolic oil – General demands and safety requirements for systems and their components |

NEN-EN-ISO 13849-1: 2016 |

Security of machines – Safety related parts of operation systems - Part 1: General principals for design |

NEN-EN-ISO 13850: 2015 |

Security of machines – Emergency stop function – Principals for design |

NEN-EN-IEC 60204-1: 2006 |

Security of machines - Electrical equipment of machines - Part 1: General demands |

NEN-EN 1525: 1997 |

Security of industrial trucks – self- driving trucks and their systems |

NEN-EN1175-1: 1998 + A1: 2010en |

Security of trucks with industrial machines – Electrical requirements - Part 1: General demands for battery driving trucks |

Software

|

Simultaneous localization and mapping is a software and hardware technology, which enables the Nipper to map its environment while positioning itself in that environment. When using SLAM, you do not need any infrastructure to direct the Nipper. It can navigate autonomously through your factory or warehouse.

The Bluebotics software allows you to independently program the Nipper and add or change any commands. Furthermore, it is possible to add other devices, such as e.g. a cleaning robot, to the Bluebotics software to enable both devices to navigate via the same map. |