Vertical transport, your logistics to a new height

TBWB is the expert in the field of intralogistics automation, we literally and figuratively take your transport process to new heights. If your logistics transport of goods takes place via several levels, the use of vertical product lifts or pallet lifts is a very efficient option, and easy to integrate, also in existing conveyor belts. We have been working for years with our partner Qimarox, a leading manufacturer of vertical conveyor lifts, pallet lifts, pallet dispensers and palletizers.

Vertical transport

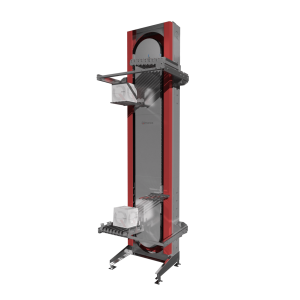

The vertical conveyor lift effortlessly, quickly and very energy-efficiently transports various products such as boxes, crates, trays or bagged goods to and from any desired level. The product is always transported upright, which prevents product deformation.

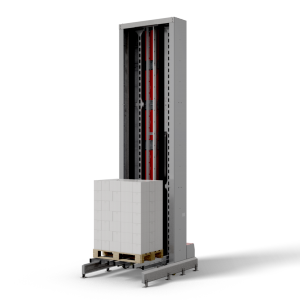

The pallet lift is very easy to integrate into your transport system and can optionally be equipped with a roller conveyor or chain conveyor. Thanks to the design with extremely reliable components, the machine requires little maintenance.

Vertical transport

The vertical conveyor lift effortlessly, quickly and very energy-efficiently transports various products such as boxes, crates, trays or bagged goods to and from any desired level. The product is always transported upright, which prevents product deformation.

The pallet lift is very easy to integrate into your transport system and can optionally be equipped with a roller conveyor or chain conveyor. Thanks to the design with extremely reliable components, the machine requires little maintenance.

The advantages of vertical conveyors and lifts

- Modular design, for quick and easy installation and modification.

- Multifunctional, so they are versatile and can combine different tasks.

- Durable, so they require little maintenance and have a high degree of operational availability.

- Their components are highly standardised, making them quick and easy to manufacture and low in price.

- Wherever possible, they use the same types of components, and which are generically available, so the costs for service and maintenance remain limited.

Prorunner vertical conveyors

|

Our Top Pick: The Prorunner MK1

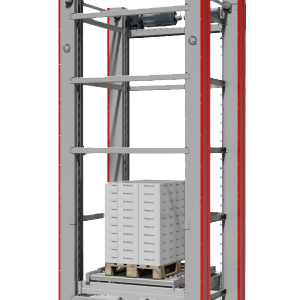

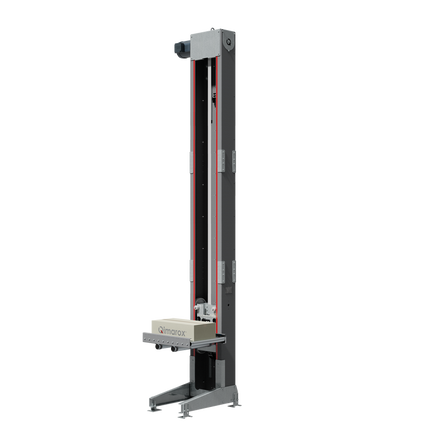

The PRORUNNER MK1 is a solid product lift that does what it should do day in day out, year in year out: raise or lower products without you having to worry about it. It is the perfect solution in capacities of up to 500 products/hour. Due to its extremely small footprint, this lift can be used in almost any fit the layout. The compact unit is very easy to integrate into your transport system and can optionally be equipped with a roller conveyor or belt conveyor. Thanks to the design with highly reliable components, the machine requires very little maintenance. In short: an easy to integrate product lift that remains affordable.

This discontinuous product lift excels in robustness and requires hardly any maintenance. Thanks to the steel structure, the construction remains extremely stable under all circumstances. By using a flat timing belt, the PRORUNNER MK1 completely silent in the up and down movement. In addition, a flat belt of this type requires virtually no maintenance. Lubrication and tensioning is no longer necessary compared to chain drive. Efficient vertical transport

The robust and low-maintenance product lift can effortlessly lift boxes, trays, bins, crates, crates or bags weighing up to 75 kg. The PRORUNNER MK1 is ideally suited for applications where the capacity is up to approx. 360 movements per hour. Thanks to the compact design, relatively little floor space is required. All this together makes the PRORUNNER MK1 an extremely efficient and financially efficient attractive solution for your vertical transport. |

|

Small footprint, big performance

|

Free input and output heights

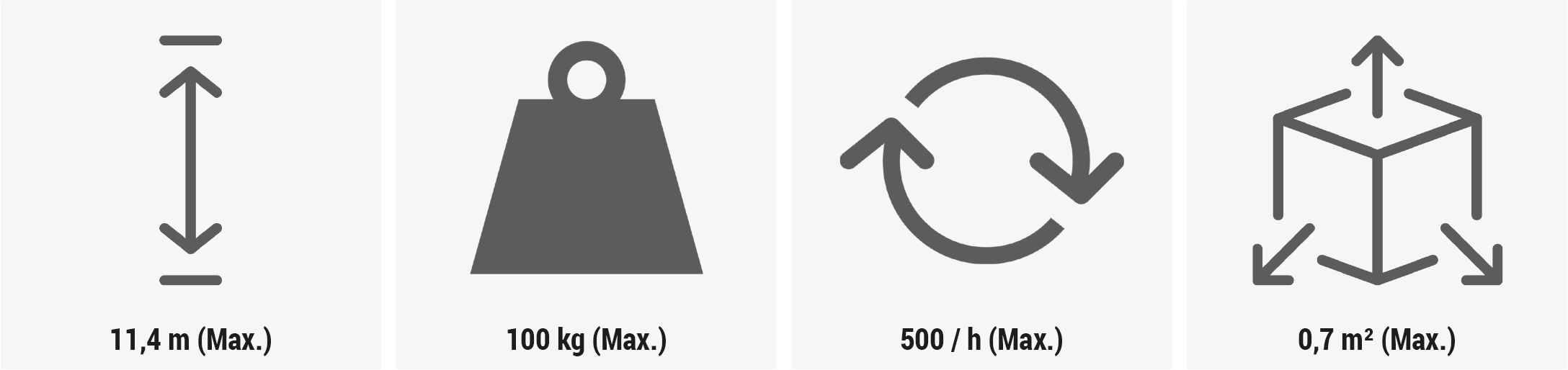

The input and output options are freely selectable and in principle not limited to a maximum height. It is also possible to operate several input or output conveyors with the Prorunner mk1, so that the lift functions as a vertical sorter. The components from which the system is built are characterized by a minimum of maintenance and an extremely long lifespan. Specifications

|

|

|

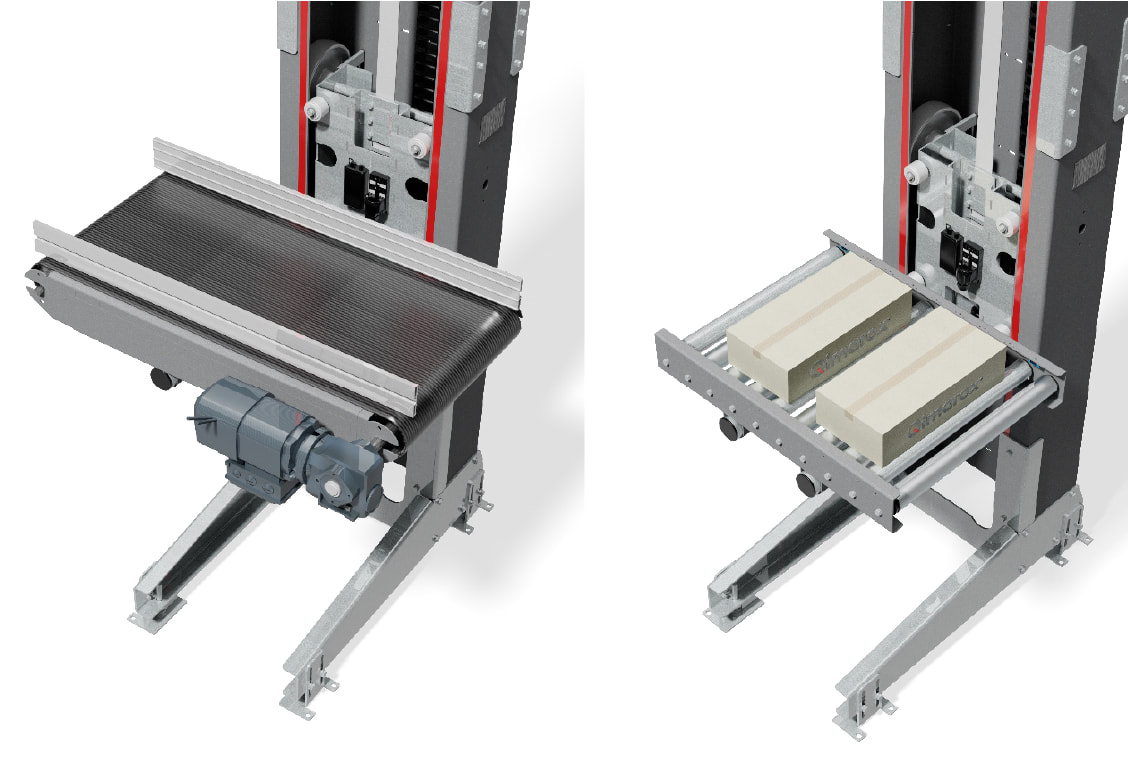

Roller deck or belt conveyor

Thanks to its modular design, the Prorunner mk1 can be perfectly adapted to the environment in which this product lift operates. A standard (driven) roller conveyor is supplied as standard as product carrier. This can optionally be replaced by a belt conveyor or other specific conveyor. It is possible to install a customer-specific carrier without modifying the construction. As a result, the lift optimally connects to the conveyor system in your production or distribution environment. |

Your vertical transport and lifts can easily be connected to any type of Interroll conveyor belt.