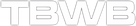

Modular platform specifically for packaged food applications

|

With the Special Hygienic Conveyor (SHC), Interroll is launching a proven modular platform especially for packaged food. That is why we offer a stainless steel platform that is easy to integrate and is a solution where basic hygiene standards are required.

Quick installation Largely pre-assembled modules speed up on-site installation. Independently adjustable side guides, infinitely adjustable supports, integrated electrical conduits and a universally applicable main hole size for attaching additional components are just some of the details that reduce installation costs. Reliable operation The robust and extensively tested design of the new modules reduces maintenance effort and ensures reliability operation of a transport system. Specifications:

|

PARTNER ROLLING ON INTERROLLTBWB has been a partner of Interroll for many years. With full expertise, Interroll systems are expertly advised and integrated by our people at our customers. Our service is trained and equipped to service your Interroll products.

For Interroll products, please contact TBWB. |

The advantages of Special hygienic conveyor belts (SHC)

|

|

Special hygienic conveyor belt modules

|

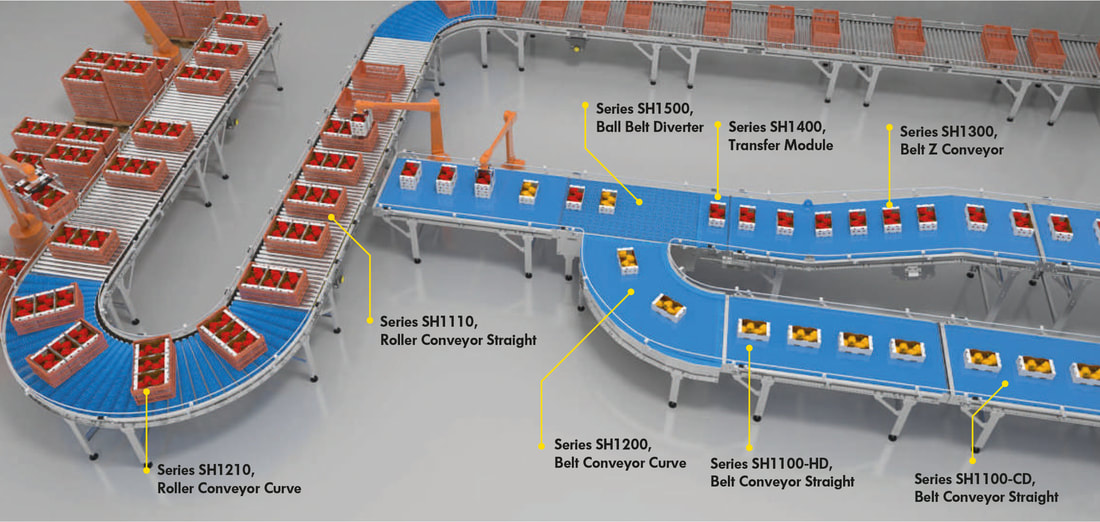

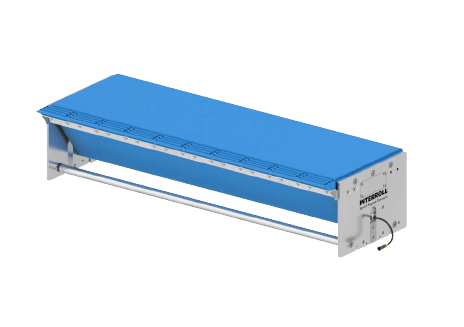

Roller Conveyor SH 1110

Straight driven The 24V-driven straight roller conveyor enables pressureless accumulation transport of unit handling with the aid of a controller. Each zone is powered by a RollerDrive connected to a fixed number of rollers via PolyVee belts that run from roller to roller.

All materials are stainless steel and the rollers, as well as the RollerDrive, MultiControl and power supply have a degree of protection of at least IPX5, which allows occasional cleaning with water and mild detergents. Vertical Divider

|

|

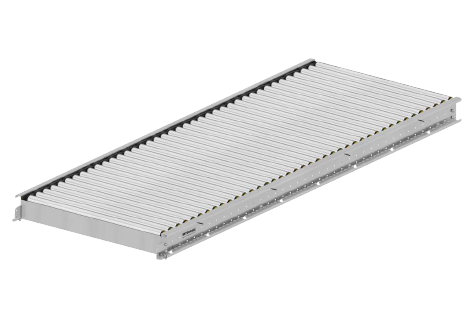

Roller Conveyor Curve SH 1210

Curve driven The 24 V powered roller curve changes the transport direction of goods that are suitable for roller conveyors. The tapered rollers maintain the alignment of the conveyed goods between the side frames. A control system enables pressureless accumulation transport. Each zone is powered by a RollerDrive connected to a fixed number of rollers via PolyVee belts that run from roller to roller.

All materials are stainless steel and the rollers, as well as the RollerDrive, MultiControl and power supply have a degree of protection of at least IPX5, which allows occasional cleaning with water and mild detergents. The tapered rollers are designed in such a way that liquids can drain onto the floor between the rollers. No water can get into the rollers. Vertical Divider

|

|

Transfer Module SH 1400

Right drive The transfer module powered with 24 V DC is a multi-flexible interface to connect the SHC platform to a third conveyor.

The transfer module reduces the gap between two conveyor belts. This is especially necessary when small, packaged foods need to be transferred to or from a conveyor belt. Packaged goods up to a size of 100 x 100 mm can be easily transferred. Vertical Divider

|

|

Diverter SH 1500

Straight-driven The SH 1500 diverter is used for diverting transport goods, preferably with smooth bottom surfaces, at different angles to the right or left.

The module is equipped with two powerful drum motors. A drum motor drives the ball belt Ammeraal Uni QNB-Ball and the second drum motor drives a steering belt, which is mounted in the upper part and at an angle of 90° below the ball belt. By starting the control belt, the direction and speed of the balls of the ball belt can be manipulated. By changing the speed of the handlebar, the deflection angle can be individually adjusted as desired. The diverter can also be used for small sorting tasks. Vertical Divider

|

|

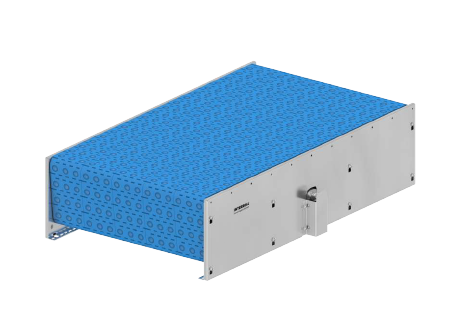

Modular conveyor belt SH 1100

Straight main drive The modular belt conveyor is used for transporting packaged small goods or goods transported in small boxes that are not suitable for roller conveyors, and for all types of goods on slopes and slopes.

The modular head drive belt conveyor uses a powerful 550W drum motor DM0080. Vertical Divider

|

|

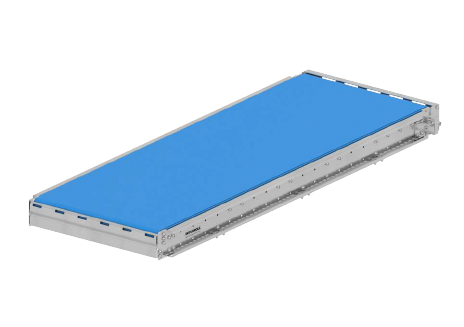

Modular conveyor belt SH 1100 CD

Straight central drive The modular belt conveyor is used for transporting packaged small goods or goods transported in small boxes that are not suitable for roller conveyors, and for all types of goods on slopes and slopes.

The mid-drive modular belt conveyor can be fitted with any drum motor between DM0080 and DM0165, allowing for a power range from 550W to 1818W. Vertical Divider

|

|

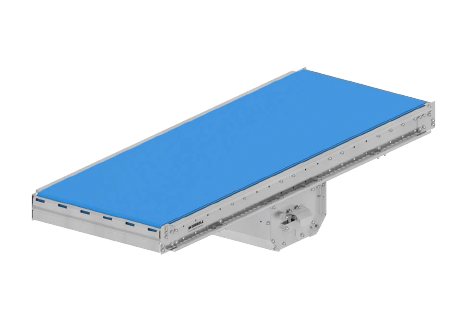

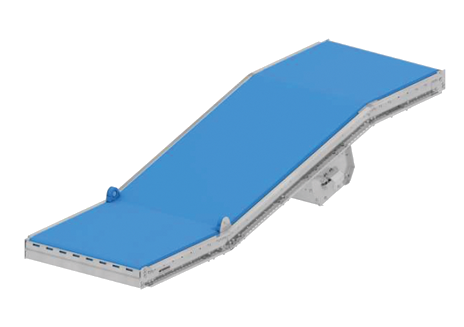

Modular conveyor belt SH 1300

Straight mid drive The Modular Curved Z Conveyor Belt is used to transport packaged small items or goods transported in small boxes that are not suitable for roller conveyors and can be used for all types of goods on slopes and declines.

The modular mid-drive Z conveyor can be fitted with any drum motor between DM0080 and DM0165, allowing for a power range of 550W to 1818W. Vertical Divider

|

|

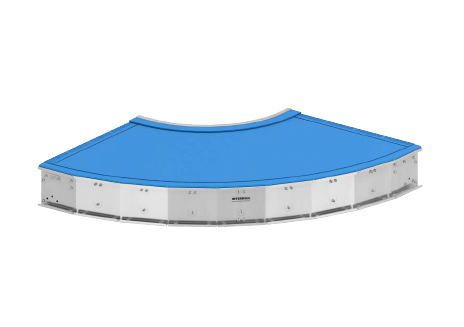

Modular belt conveyor SH 1200

Curve driven The modular belt bend is used for transporting packaged small goods or goods transported in small boxes that are not suitable for roller conveyors.

It is the first drum motor driven modular belt curve on the market and as such fits perfectly with the flowing silhouette of the other SHC modules. Vertical Divider

|

Specially developed for the SHC modules

|

Multicontrol BI

The MultiControl is a control with four zones. This means that a maximum of four RollerDrive EC5000 BI and four zone sensors can be connected. By using Y-cables, four additional inputs or outputs can be connected. The connections can be configured individually.

MultiControl is suitable for several protocols. PROFINET, EtherNet/IP and EtherCat can be used via simple switching. |

Frequency Inverter FC 1000

|

The Interroll FC 1000 is a state-of-the-art decentralized frequency converter and can be used, among other things, to drive Interroll drum motors in logistics applications, food processing, beverage industry and packaging applications. It is suitable for synchronous and asynchronous motors and controls sensorless control and operation with encoder feedback for positioning tasks.

The housing consists of aluminum; there is a version with a special surface finish for the food and beverage industry. The frequency converter is available in two mounting variants: on the side frame of a conveyor belt or mounted directly on the shaft of a drum motor. |

Download the Special hygienic conveyor belts (SHC) brochurex

|