TBWB is your partner for every sorting system in CEP logistics!

Sorting systems ensure that goods can be sorted automatically. This can save a lot of money for companies in labor costs. Selecting the right sorting system is not an easy task. Only after a thorough analysis of the products to be sorted based on the required capacities, the right system can be chosen.

Sorting systems are available, each with its own characteristics and suitable for a wide range of applications.

TBWB is your partner for the selection of the right sorting system. TBWB is product independent and supplies any desired sorting system.

Sorting systems are available, each with its own characteristics and suitable for a wide range of applications.

TBWB is your partner for the selection of the right sorting system. TBWB is product independent and supplies any desired sorting system.

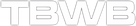

HPP SORTERWith the High Performance Conveyor Platform (HPP), the advantages of a flexible modular system of conveyor modules are now also available to system integrators and end users in the CEP industry. |

MCP SORTERFaster, more flexible and even quieter. The new high-performance system can process up to 20,000 transported goods per hour. With this new solution, much heavier and larger goods can also be sorted. You can easily transport boxes, bins and crates within your warehouse or warehouse with the Interroll Modular Conveyor Platform (MCP). |

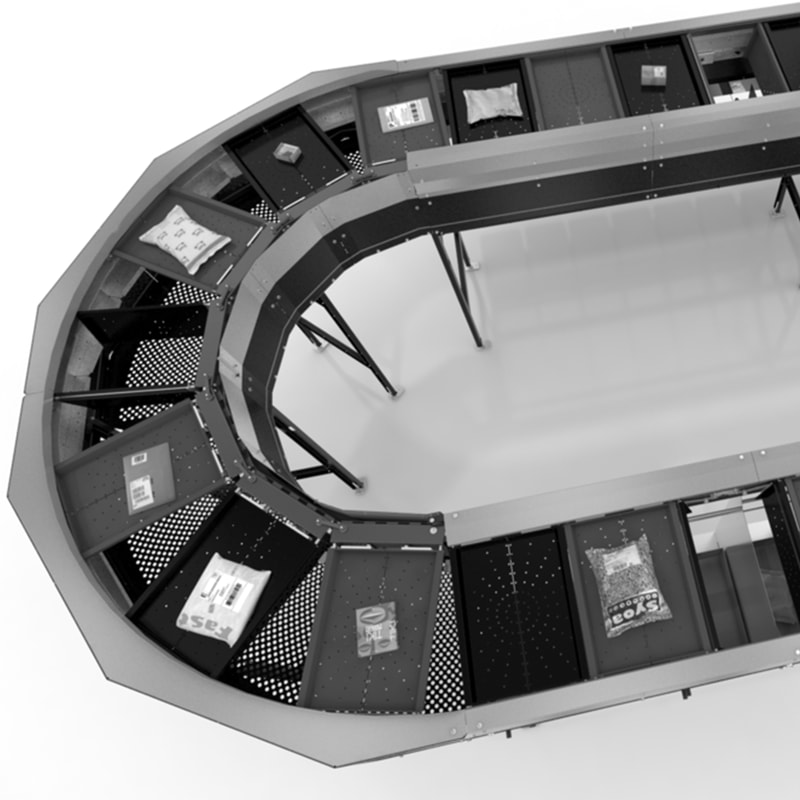

CROSSBELT SORTERTBWB's crossbelt sorters are the best solution when working with large volumes that need to be sorted simultaneously. With a cross-belt sorter we guarantee error-free sorting at high speed. |

SPLIT-TRAY SORTERA Bombay sorter, also known as a flat sorter or split-tray sorter, is used for automated sorting of small lightweight products at high speed. These products are often too small and light to be handled by a typical conveyor system. This includes: clothing in bags, jewellery, pharmaceuticals, CDs, mail, books and small packages. |

POP-UP SORTERA pop-up sorter ensures smooth, fast and intelligent sorting of a wide range of products. Two rows of pop-up rollers lift and rotate individual items so they are always in line with the output. These sorters are ideal for parcels of all shapes and sizes. The modular design allows for an easy configuration that can always be adjusted thanks to the plug & play system. For example, the ability to change direction makes it possible to switch efficiently between inbound and outbound sorting. They can also be installed in extremely narrow buildings and spaces. |

MANUAL SORTERSManual sorters, also called bio sorters, can be chosen based on, among other things, the required capacity and the available budget. You have a manual sorting system or a (semi-)automatic sorting system. Operators (persons) are required to place/move the products directly in the sorting solution. Examples of manual sorters are: Put-to-light (sort-to-light), Pick-to-light, Scan-to-sort, Touch-to-sort, Screen-to-sort. |

Sorting systems ideal for CEP logistics!

The sorting systems that TBWB offers are ideal for CEP logistics. The term CEP is the abbreviation for “Courier, Express Parcel Service”. It refers to postal and logistics companies that mainly transport shipments with relatively low weight and volume. Think of letters, small packages, documents or small items.

Our sorting systems are very suitable for these items and can be standardized in terms of dimensions and weight. This makes it easy to fully or partially automate the handling and sorting of the objects to be transported. In this way, shipments can be transported in a short time and with a high return. Would you like to know which sorting solution suits your company best? Contact us! We are happy to give you advice without obligation.

Our sorting systems are very suitable for these items and can be standardized in terms of dimensions and weight. This makes it easy to fully or partially automate the handling and sorting of the objects to be transported. In this way, shipments can be transported in a short time and with a high return. Would you like to know which sorting solution suits your company best? Contact us! We are happy to give you advice without obligation.

Different types of sorting systems that TBWB also can offer:

- MCP-sorter

- Cross-belt sorter

- Split-tray sorter (Bombay sorter / Flat sorter)

- Pop-up sorter

- Pusher sorter

- Shoe sorter

- Manual sorters (Bio sorter)