Picking robots, flexible, scalable and location independent

The Rowa VMax is an automated storage and order picking robot for intelligent order picking. This picking machine accelerates the processes of incoming goods and optimizes warehouse management and inventory. It is the solution for the safe and fast order picking of small and large order volumes. This smart robot picking machine is available in multiple designs and flexible in width, height and length.

You can see below which models TBWB can supply you.

You can see below which models TBWB can supply you.

|

|

Kosmetik Fuchs - Case Study :

|

Storage and issue per SKU with Rowa VMax micro as/rs

Advantages of a Rowa Vmax picking robot

|

|

-

VMax 130

-

Vmax 160

-

Vmax 210

-

Vmax 320

<

>

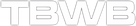

BD Rowa Vmax 130

Properties |

Slimline Vmax |

Width |

1.33 m |

Height |

2.12 m - 3.52 m (in 5 cm intervals) |

Length |

2.68 m - 15.17 m (in 48 cm intervals) |

Sound Level |

48,3 dB (A) |

Possible locations |

Ground floor, basement, upper floor |

Input and output times |

Input Approx. 3 seconds (Direct availability for over-the-counter sales) Output Approx. 8 – 12 seconds (up to 6 packs at the same time possible) |

Square packs Round packs |

Min. pack size (DxWxH) 35x15x15 mm Max. pack size (DxWxH) 230x140x145 mm Weight 5 g – 1,000 g Min. pack size Ø 45 mm, height: 15 mm Max. pack size Ø 140 mm, height: 145 mm Weight 5 g – 800 g |

Barcodes |

Identification and reading of PZN, PZN8, EAN, and 2D barcodes |

Electrical Parameter |

AC 230 V, 50/60 Hz, 8 A |

Power consumption |

In operation 650 W with one picking head 780 W with two picking heads In standby mode 348 W with one picking head 379 W with two picking heads |

Safety |

System protection thanks to uninterrupted power supply (UPS) , backup computer, remote monitoring |

Options |

2nd picking head 2nd input belt Rowa™ Label (labeling) BD Rowa™ cleaning module BD Rowa™ System backup BD Rowa™ ProLog™ external (fully automatic input) BD Rowa™ refrigerated unit (Special construction on request) |

Conveyor technology |

Conveyor belt, servo controlled lift, spiral chute Ø 400 mm, possible to connect up pneumatic tube |

Colors |

White (RAL 9016) , anthracite (RAL Design 000-25-00) |

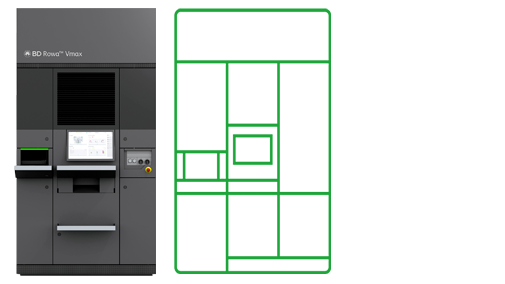

BD Rowa Vmax 160

Properties |

All-rounder |

Width |

1.63 m |

Height |

1.72 m - 3.52 m (in 5 cm intervals) |

Length |

2.68 m - 15.17 m (in 48 cm intervals) |

Sound Level |

48,3 dB (A) |

Possible locations |

Ground floor, basement, upper floor |

Input and output times |

Input Approx. 3 seconds (Direct availability for over-the-counter sales) Output Approx. 8 – 12 seconds (up to 9 packs at the same time possible) |

Square packs Round packs |

Min. pack size (DxWxH) 35x15x15 mm Max. pack size (DxWxH) 230x140x145 mm Weight 5 g – 1,000 g Min. pack size Ø 45 mm, height: 15 mm Max. pack size Ø 140 mm, height: 145 mm Weight 5 g – 800 g |

Barcodes |

Identification and reading of PZN, PZN8, EAN, and 2D barcodes |

Electrical Parameter |

AC 230 V, 50/60 Hz, 8 A |

Power consumption |

In operation 650 W with one picking head 780 W with two picking heads In standby mode 348 W with one picking head 379 W with two picking heads |

Safety |

System protection thanks to uninterrupted power supply (UPS) , backup computer, remote monitoring |

Options |

2nd picking head 2nd input belt Rowa™ Label (labeling) BD Rowa™ cleaning module BD Rowa™ System backup BD Rowa™ ProLog™ external (fully automatic input) BD Rowa™ refrigerated unit BD Rowa™ MedPort BD Rowa™ iProLog |

Conveyor technology |

Conveyor belt, servo controlled lift, spiral chute Ø400 mm, possible to connect up pneumatic tube |

Colors |

White (RAL 9016) , anthracite (RAL Design 000-25-00) |

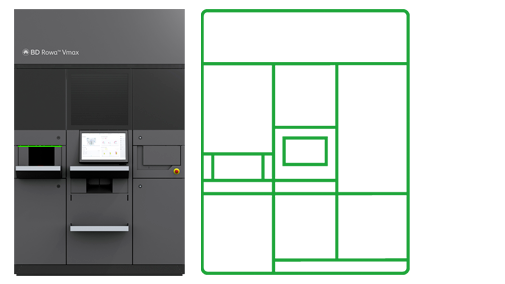

BD Rowa Vmax 210

Properties |

Strong performance |

Width |

2.13 m |

Height |

2.12 m - 3.52 m (in 5 cm increments) |

Length |

3.20 m - 15.04 m (in 32 cm increments) |

Sound Level |

50,9 dB(A) |

Possible locations |

Ground floor, basement, upper floor |

Input and output times |

Approx. 3 seconds (direct availability for sales counter, up to 14 packs possible at the same time) Output Approx. 8 – 12 seconds (up to 14 packs at the same time possible) |

Square packs Round packs |

Min. pack size (DxWxH) 35x15x15 mm Max. pack size (DxWxH) 500x250x150 mm Weight 5 g – 1,000 g Min. pack size Ø 45 mm, height: 15 mm Max. pack size Ø 140 mm, height: 145 mm Weight 5 g – 800 g |

Barcodes |

Identification and reading of PZN, PZN8, EAN, and 2D barcodes |

Electrical Parameter |

AC 230 V, 50/60 Hz, 8 A AC 120 V, 50/60 Hz, 16 A |

Power consumption |

In operation 391 W with one picking head / 830 W with 2 picking heads In standby mode 158 W with one picking head / 158 W with 2 picking heads In power saving mode 76 W with one picking head / 76 W with 2 picking heads |

Safety |

System protection thanks to uninterrupted power supply (UPS) , backup computer, remote monitoring |

Options |

Second picking head Second input belt BD Rowa™ ProLog external (fully automated stock input) |

Conveyor technology |

Conveyor belt, servo controlled lift, spiral chute Ø400 mm, possible to connect up pneumatic tube |

Colors |

White (RAL 9016) , anthracite (RAL Design 000-25-00) |

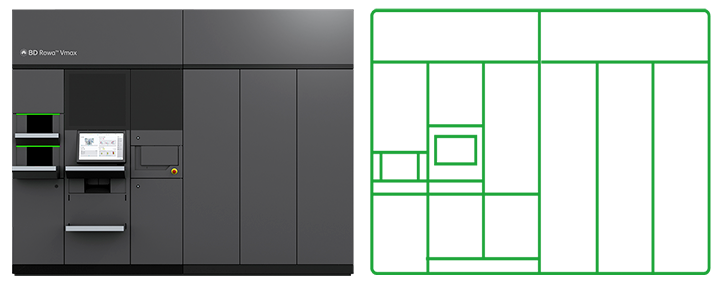

BD Rowa Vmax 320

Properties |

Square Floor Areas |

Width |

3.23 m |

Height |

2.02 m - 3.02 m (in 5 cm intervals) |

Length |

3.58 m - 5.98 m (in 48 cm intervals) |

Sound Level |

Average sound pressure level LpA,m 49,1 dB (A) |

Possible locations |

Ground floor, basement, upper floor |

Input and output times |

Input Approx. 3 seconds (Direct availability for over-the-counter sales) Output Approx. 8 – 12 seconds (up to 9 packs at the same time possible) |

Square packs Round packs |

Min. pack size (DxWxH) 35x15x15 mm Max. pack size (DxWxH) 230x140x145 mm Weight 5 g – 1,000 g Min. pack size Ø 45 mm, height: 15 mm Max. pack size Ø 140 mm, height: 145 mm Weight 5 g – 800 g |

Barcodes |

Identification and reading of PZN, PZN8, EAN, and 2D barcodes |

Electrical Parameter |

AC 230 V, 50/60 Hz, 8 A |

Power consumption |

In operation 650 W with one picking head In standby mode 348 W with one picking head |

Safety |

System protection thanks to uninterrupted power supply (UPS) , backup computer, remote monitoring |

Options |

2nd input belt Rowa™ Label (labeling) BD Rowa™ System backup BD Rowa™ iProLog™ (integrated fully automatic input) BD Rowa™ cleaning module BD Rowa™ ProLog™ external (fully automatic input) BD Rowa™ refrigerated unit (height 2,300, 2,900 mm) |

Conveyor technology |

Conveyor belt, servo controlled lift, spiral chute Ø400 mm, possible to connect up pneumatic tube |

Colors |

White (RAL 9016) , anthracite (RAL Design 000-25-00) |

TBWB Skubin for the Rowa picking robot

BD ROWA™ PROLOG - Fully automatic storage of goods 24/7

|

Time-saving

The manual workload is kept to a minimum, the BD Rowa™ ProLog separates, measures, scans and inputs. |

Process optimization

The additional expiration date recognition function optimizes your inventory management. In the long run, this saves both work time and money. |

Increased security

Automatic entry, based on the barcode and measurements, virtually eliminates mix-ups. |

BD ROWA™ PROLOG in action!

BD ROWA™ ORDER BUFFER - Efficient order processing

|

|